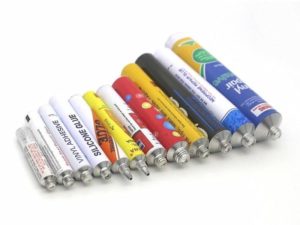

“White tube” or “white painted tube” is a common name to specify tubes in white color. For white-colored aluminum collapsible tubes, most people get the impression that the tubes are printed white. Actually they are “coated” white. What are the differences? Here are some points to know about white tubes.

#1. Aluminum tubes are coated with saturated polyester resin, which is usually in white color but can also be made in other colors. This resin has good flexibility and adhesion. As it adheres to tube surface, it offers excellent film for protection. The flexible film is resistant to scratch.

#2. In production, aluminum tubes should be “baked” at 285 degree Fahrenheit for a few minutes after being coated with the resin. The heat helps to smooth the resin over tube surface so that the coating spreads out evenly.

#3. Once the tubes are removed from the oven and cool down, they are ready for print. Well-coated tubes enhance the quality of printing as the coating provides smooth background for artwork and text presentation.

#4. There are cases in which coated tubes are used without further printing. For example, white tubes are commonly used in laboratories. They can also be used for packaging product samples. Some product developers choose to apply self-adhesive label on the tubes instead of printing artwork on them.

#5. Compared to the original silver/grey aluminum color, the white coating drastically changes the appearance of aluminum tube. It gives the packaging tubes a softer and warmer touch to appeal consumers.

Xin Yi manufactures aluminum packaging tube in different specifications. Custom services are offered. Tubes are used for packaging adhesive glue, toothpaste or cosmetics. For product inquiries, please contact Xin Yi sales team today!