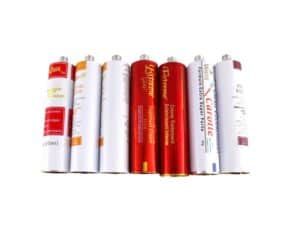

Aluminum collapsible tubes are a popular choice for packaging a variety of viscous products, such as toothpaste, adhesive glue, cosmetic creams, and medical ointments. They offer durability, protection from contamination, and a user-friendly design. An essential aspect of their appeal lies in the printing techniques used to decorate and label these tubes. Among the various printing methods available, offset printing stands out for its exceptional quality and efficiency. Do you know much about the benefits of offset printing for collapsible aluminum tubes?

Understanding Offset Printing

Offset printing is a widely used printing technique where an inked image is transferred from a plate to a rubber blanket, and then to the printing surface. This method is highly effective for producing high-quality prints with excellent color fidelity and detail. Unlike digital or screen printing, offset printing can accommodate a wide range of designs and is particularly well-suited for large production runs, making it ideal for packaging solutions like collapsible aluminum tubes.

Benefit 1: High-Quality Output

One of the most significant advantages of offset printing is the superior print quality it delivers. The process allows for high quality images and vibrant colors, which are crucial for attracting consumers and conveying a premium brand image. Offset printing can reproduce fine details and subtle gradients with precision, ensuring that every design element stands out. For industries such as cosmetics and pharmaceuticals, where packaging must reflect product quality and brand integrity, offset printing is an excellent choice.

Benefit 2: Cost-Effectiveness for Large Runs

Offset printing becomes increasingly cost-effective as the quantity of the production run increases. The initial setup costs, including creating the printing plates, are higher compared to some other printing methods. However, these costs are spread over the entire run, reducing the per-unit cost significantly. For large-scale production, offset printing offers an economical solution that delivers high-quality results without breaking the budget. This cost efficiency makes it a preferred choice for manufacturers looking to produce large quantities of collapsible aluminum tubes.

Benefit 3: Consistency and Reliability

Consistency in print quality is crucial for maintaining brand standards, especially when producing large batches of packaging. Offset printing excels in delivering consistent and reliable results across the entire production run. This method ensures uniformity in color, image sharpness, and overall print quality, helping brands maintain a cohesive look and feel for their products. For companies that prioritize brand integrity, the reliability of offset printing is a significant advantage.

Benefit 4: Speed and Efficiency

Offset printing is known for its fast production rates, making it an ideal choice for meeting tight deadlines and large-scale production demands. Once the initial setup is complete, the printing process itself is highly efficient, allowing for quick turnaround times. This speed is essential for manufacturers who need to respond to market demands swiftly and ensure their products are available when consumers need them. The efficiency of offset printing helps companies streamline their production processes and reduce lead times.

Benefit 5: Environmental Considerations

Modern offset printing practices have evolved to incorporate eco-friendly options, addressing growing environmental concerns. Many printers now use sustainable inks and materials that reduce the environmental impact. Additionally, the offset printing process generates less waste compared to other methods, and many components, such as printing plates, can be recycled. These eco-friendly practices make offset printing a more sustainable choice for manufacturers who are committed to reducing their carbon footprint and promoting environmental responsibility.

Is Offset Printing Your Choice?

In summary, offset printing offers numerous benefits for collapsible aluminum tubes, including high-quality output, cost-effectiveness for large runs, consistency and reliability, speed and efficiency, and environmental considerations. These advantages make offset printing a preferred choice for manufacturers looking to produce visually appealing and durable packaging.

If you’re considering packaging solutions for your products, offset printing on collapsible aluminum tubes could be the ideal option to meet your needs and enhance your brand’s appeal. For more information on how offset printing can benefit your industry, cosmetics or phamaceuticals, contact Xin Yi today and discover the possibilities for your brand: sales@tubenaire.net