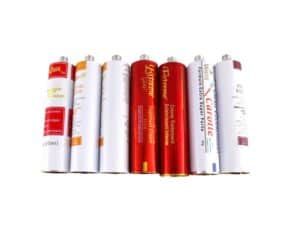

Aluminum collapsible tubes have long been the preferred packaging material for various paste products, such as adhesive glue, hand cream, cosmetic gel, and medical ointments. Metal squeeze empty tube provides a sealed and aesthetically pleasing packaging solution. The functionality of aluminum packaging tubes extends beyond mere sealing; it also affects the quality and integrity of the contents within. In this article, we will introduce seven key points to evaluate the quality of aluminum collapsible tubes, ensuring that the chosen packaging solution not only withstands the test of time but also effectively protects its contents.

1. High-Quality Raw Materials:

The foundation of any quality aluminum collapsible tube lies in the raw materials used. Choose packaging tubes made from high-quality aluminum slugs, ensuring durability and protection from external contaminants. Carefully selected materials ensure that the metal squeeze empty tube maintains its structural integrity, preventing leakage or contamination.

2. Thickness of the Tube Wall:

The thickness of the tube wall plays a crucial role in the sturdiness of a metal squeeze empty tube. A sufficiently thick tube wall helps increase the strength of the packaging material to resist external pressure. Carefully measure whether the thickness of the tube wall falls within the standard range. The thickness must strike a balance to ensure that the tube is both flexible and robust.

3. Surface Smoothness and Coating Uniformity:

The appearance of aluminum tubes as packaging materials is highly valued. A clean and smooth surface enhances visual appeal, improves texture, and prevents corrosion. In addition, appropriate internal and external coatings, such as epoxy resin or varnish, must be applied evenly and adhere well. Coatings provide additional protection against environmental factors, ensuring the longevity of the packaging material.

4. Evaluate the Sealing Effect:

The sealing effect of aluminum packaging tubes is a crucial part that requires careful inspection. A well-folded and sealed tube effectively prevents leaks and eliminates the risk of rupture. The internal lining at the opening of the aluminum tube should be even and well-adhered. After folding, the metal squeeze empty tube should be smooth and uniform, with no irregularities. Any minor cracks could compromise the sealing effect, potentially damaging the quality of the product.

5. Cap Fit:

The cap, or the plastic or metal screw cap that fits onto the nozzle of the aluminum collapsible tube, is essential for securely storing the contents. Inspect and test the airtightness of the cap to ensure easy use, proper sealing, and prevention of potential leaks.

6. Conduct Toughness Tests:

To assess the structural resilience of the aluminum tube, perform toughness tests using specialized equipment. Lay the tube flat and apply pressure to observe its ability to rebound after external force is applied. A high-quality aluminum tube should demonstrate good flexibility, withstand bending without excessive rebound, as overly rigid tubes may compromise the sealing effect after folding.

7. Consider Sustainability:

In the current era of heightened environmental awareness, the sustainability of packaging materials is of paramount importance. Aluminum slug, being 99.7% pure, is recyclable. Some manufacturers even use recycled aluminum material to produce tubes, aligning with consumers’ high standards for environmental protection. Opting for sustainable packaging not only aligns with eco-friendly practices but also enhances the company’s and brand’s image.

Choosing the right aluminum packaging tube is a meticulous process that requires a comprehensive evaluation of various factors. By considering material quality, tube wall thickness, sealing effectiveness, surface aesthetics, cap fit, conducting toughness tests, and ensuring sustainability, brands can secure not only effective packaging for their products but also demonstrate a deep commitment to product quality and environmental responsibility.

Guangzhou Xinyi Enterprise is a leading manufacturer of metal squeeze empty tubes, supplying tubes ranging from 10mm to 32mm in diameter. Our soft tubes can be customized with the client’s brand logo and text, and we offer processing based on the attributes of the client’s products. Adhesive glue tubes, cosmetic soft tubes, toothpaste tubes, white paint tubes. For inquiries, please contact us at: +86-20-86172272