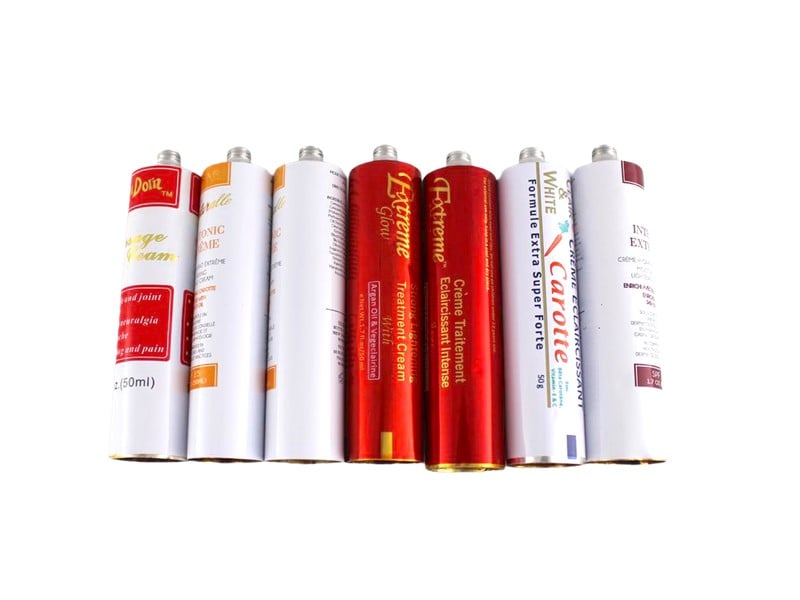

Aluminum collapsible tubes are a popular packaging choice for a wide range of cosmetic products, from hand creams to toothpaste. The design of these cosmetic tubes is crucial in conveying a professional brand image and attracting consumers. Offset printing plays a key role in this process, enabling the creation of detailed and vivid designs. Here are seven essential tips to help you create outstanding offset printing on cosmetic aluminum tubes.

Basics of Cosmetic Tube Printing

Offset printing involves transferring an ink image from a printing plate to a rubber blanket, which then transfers the image onto the surface of the packaging material. This method is known for its excellent color fidelity and detail resolution, allowing for vivid and intricate designs.

Understanding these basics can help brand owners optimize their designs to achieve the desired effect. Here are seven practical tips to get you started:

Tip 1: Use High-Resolution Images

High-resolution images ensure that design elements are clear and sharp. For offset printing, use images with a resolution of at least 300 dpi. This level of detail prevents pixelation and blurriness, making your packaging look professional and attractive. High-resolution images enhance the overall appearance of the product and improve consumer perception.

Tip 2: Incorporate Vector Graphics

Vector graphics are scalable and maintain clarity at any size, making them ideal for printing. Unlike raster graphics, which can become pixelated and blurry when enlarged, vector graphics are created using mathematical equations, ensuring they remain clear and precise. Use design software to create vector graphics for logos, icons, and other elements that need to stay sharp at any size.

Tip 3: Use Spot Colors for Consistency

Spot colors are pre-mixed inks used in offset printing that allow for precise color matching. They are ideal for maintaining brand consistency, especially for specific brand colors. Using spot colors for logos, brand names, and other key design elements ensures the same color effects in different batches, maintaining a consistent brand image and a professional, cohesive look. Xinyi uses Pantone color inks to produce cosmetic aluminum tubes.

Tip 4: Pay Attention to Typography

Typography is crucial in packaging design. Choose fonts that are clear, easy to read, and complement the overall design. Adjust font size, spacing, line height, and color contrast to ensure readability. Avoid overly fancy fonts for small text, and always proofread to avoid errors. Clear, well-integrated typography effectively conveys the brand message and enhances the overall aesthetic of the packaging.

Tip 5: Consider Printing Range Limitations

When designing graphics for aluminum cosmetic tube printing, be mindful of the printable range limitations. The starting and ending points of the cylindrical aluminum tube often overlap slightly during printing, affecting the design. It’s advisable to use a single color in the overlap area. Additionally, you want to make sure the graphics near the tail end of the tube would not be covered when sealed. Generally, keep the design at least 1/8 inch (3 mm) away from the edge. Properly setting the graphic design range ensures a refined and professional appearance.

Tip 6: Optimize for Metal Surfaces

Printing on aluminum surfaces presents unique challenges and opportunities. It’s common to apply a white or creamy base coating to the surface of aluminum cosmetic tubes before color offset printing to help the ink adhere evenly. Alternatively, using a clear base coating and printing on the bare aluminum can utilize the metallic sheen for a high-end, striking visual effect.

Tip 7: Test Your Design

Before mass production, always proof your design. Create print drafts and trial samples to check color, layout, and overall appearance. Identify potential issues and make necessary adjustments to ensure the final product meets expectations.

Offset Printing Brings Aluminum Tubes to Life

Offset cosmetic tube printing transforms plain metal tubes into colorful packaging that captures consumers’ attention. By using high-resolution images, choosing the right spot colors, combining vector graphics, and considering the unique properties of aluminum, designers can create beautiful and impactful packaging. Don’t forget to sample your designs before full production to ensure the best results. With these tips, you can produce high-quality, eye-catching aluminum cosmetic tube packaging that enhances your brand image and wins consumers’ favor.

Guangzhou Xinyi Enterprise Ltd produces cosmetic aluminum tubes, ranging from 3 ml to 100 ml, suitable for beauty creams, hand creams, nail glue, and more. Xinyi helps you create outstanding offset designs. Contact us for quotation information and free samples: sales@tubenaire.net